Sustainable petrochemicals: Markets explore multiple routes to a greener future

Recycled plastics have been around for years as a premium option for those aiming to reduce their environmental footprint while continuing to use these materials which, due to their remarkable versatility, have become ever more entrenched in daily modern life.

But despite steady growth, this segment has always been a relatively niche part of the ever-expanding petrochemicals market. Now, however, the growing urgency of the global drive toward net-zero and the energy transition is encouraging companies to innovate even more in the quest to provide premium sustainable petrochemicals. This in turn is driving rapid growth in demand for the feedstocks to produce them, and resulting in an ever-tighter market.

Chief among these innovations are chemical plastic recycling and bio-plastics – which refers both to plastics that are made using bio-feedstocks or plastics that are biodegradable at the end of their lifecycle. Over recent years, traditional petrochemical companies have been announcing sizeable investments into research and production of these types of plastics left, right and center. Carbon reduction efforts are also taking off, although low-carbon petrochemical markets are nascent and yet to see liquidity of any significance.

Over 7.8 million mt/year of capacity was certified for bio-polymer production across the globe at the end of 2021, according to ISCC data, and over 1.4 million mt/year of chemical recycling capacity is expected to start up by 2025, according to S&P Global Commodity Insights research. While this pales in significance compared to the overall size of the plastics market – production is estimated at over 300 million mt/year – what is eye-catching is the rapid pace of growth, and the number of established petrochemical companies that are getting behind it.

Legislation, growing public awareness and companies' voluntary adoption of ESG principles will likely continue driving growth in demand for green petrochemical solutions. According to the Ellen MacArthur Foundation, a UK-based circular economy proponent, companies representing 20% of all plastic packaging produced globally have a commitment to recycled and recyclable plastic, and to decrease their reliance on virgin (fossil fuel-derived) plastics.

However, there are major challenges to overcome.

Addressing feedstock supply issues will be key to driving scalability, greater competition and further technological innovation across the supply chain

Inadequate feedstock availability is an important one, whether that be sourcing post-consumer plastic waste, for either mechanical or chemical recycling, or sourcing of first-, second- or third- generation feedstock for bio-polymer production.

For recycled plastic, this means navigating complex waste collection systems that are inconsistent not just across different regions, but even within the same country. For bio-plastics, petrochemical companies will need to compete for bio-naphtha – the primary feedstock – with the gasoline blending and agriculture markets.

Addressing feedstock supply issues will be key to driving scalability, greater competition and further technological innovation across the supply chain.

The supply and demand imbalance in the recycled plastic markets has become an all too familiar issue over the pandemic years. Supply of post-consumer waste has fallen because the drop in tourism and large-scale events has reduced demand for on-the-go products. Meanwhile, government and industry commitments to recycle plastics have continued to pile on demand, particularly in markets such as consumer goods, automotive and construction.

End-2021 data from CalRecycle revealed that only seven out of the 69 beverage manufacturers in California met the first recycled content threshold in 2020, ahead of the implementation of a state bill requiring a minimum of 15% post-consumer recycled polyethylene terephthalate, or PET, to be used in beverage bottles from January 2022. Part of the issue is that there is just not enough material.

Reclamation capacity in the US would need to increase by at least 50% from current capacity to meet announced recycled PET commitments by companies operating in the US, according to a 2021 study by the American Institute for Packaging and the Environment.

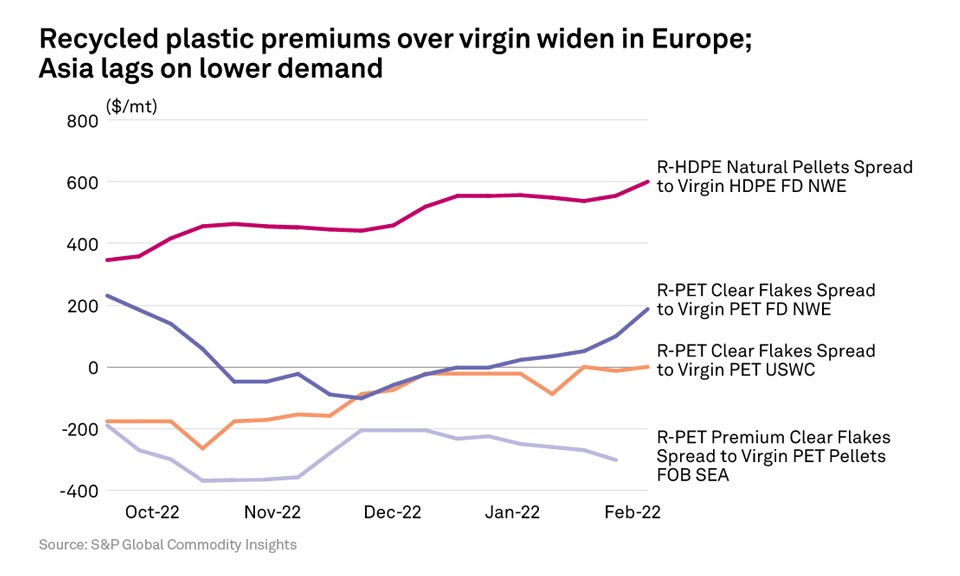

This problem is not specific to the US. Global recycled plastic prices followed a strong upward trend throughout 2021, as a result of growing demand, acute supply shortages and shipping disruptions that have cut off vital sources of supply like Southeast Asia from the demand centers of Europe and the US.

The key petrochemical feedstock for bio-plastic production is bio-naphtha, which can be used as a direct substitute for fossil-based naphtha.

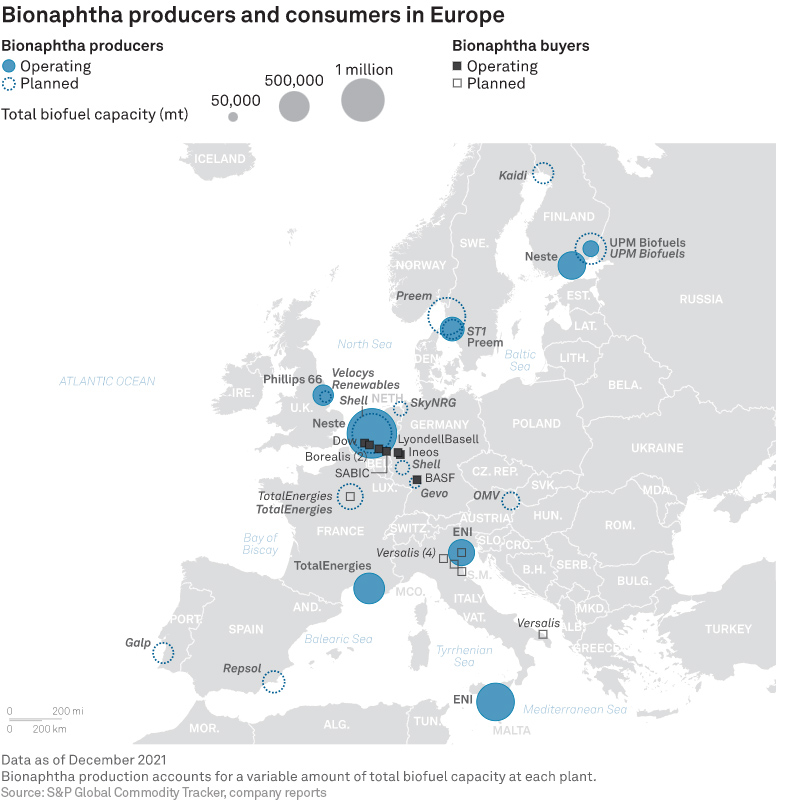

Current European bio-naphtha supply is estimated at 150,000-250,000 mt annually, with expectations for supply to double or even surpass 1 million mt/year in the coming years, according to the NOVA Institute. Even in the most bullish scenario, bio-naphtha supply would not meet demand growth expectations.

Bio-polymers were seen as a green solution to inadequate supply in recycled markets. But now, a solution is needed to address the shortage in bio-polymers

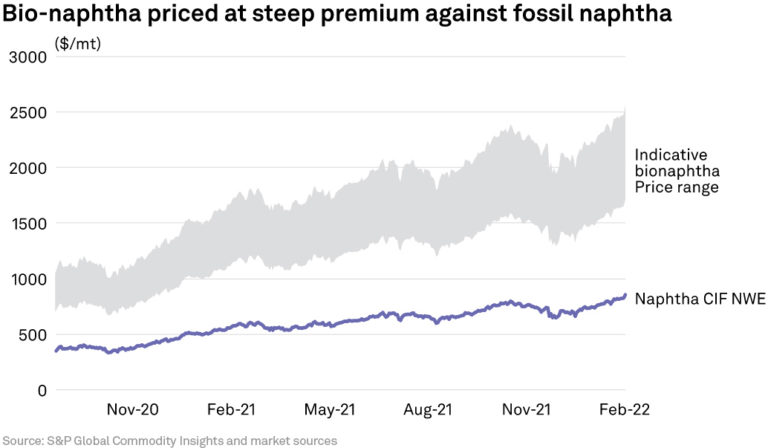

As a result, bio-naphtha is commonly priced at steep premiums against its fossil alternatives, which can range between double to three times the price of the Platts naphtha CIF NWE benchmark.

Moving forward, the petrochemicals markets are going to have to attract this key sustainable feedstock in the face of much competition – from the food industry and fuels – if it is to scale up and supply sufficient quantities of bio-polymers.

For some, bio-polymers were seen as a green solution to inadequate supply in recycled markets. But now, a solution is needed to address the shortage in bio-polymers.

Several petrochemical producers are stepping up carbon-reduction efforts in sectors such as methanol, olefins and polymers, including PET. Solutions include using renewable energy in cogeneration power plants, scaling up bioproduction, carbon capture, utilization and storage technology, and shifting away from fossil fuel-based feedstocks to lower-carbon alternatives like hydrogen.

But the results so far are well short of the mark. More coherent policy frameworks, particularly in emerging petrochemical hubs, will be needed to lower investment barriers for these new technologies. Industry efforts will be needed to standardize how the carbon intensity of specific petrochemical products is measured and reduced – or offset in carbon credits markets. Further standardization and liquidity would boost competition and technological innovation, and facilitate the formation of prices and benchmarks that ultimately would determine the direction and pace of change through the energy transition.

There are multiple routes to a greener future for petrochemicals and they will need to be explored simultaneously for the industry to truly go green. To reach the stage where a plastic bottle, for instance, is made from part recycled content, part bio content and part low-carbon certified material, all of these markets will require efforts to drive commoditization on a global scale.

This piece was first published in February 2022 under the special report Breaking Barriers to Accelerate Energy Transition

News

Geopolitical pressures — including rising resource nationalism and a year in which over 50% of countries will be having elections — as well as inflationary pressures have sent energy transition progress into “discord.” A specialty chemicals panel session held March 19 at the World Petrochemical Conference by S&P Global in Houston, Texas, tracked the challenges and opportunities of the energy transition for the industry. Speaking at the session, Roman Kramarchuk, head of climate markets and policy analytics at S&P Global Commodity Insights, said that if the short-term scenario continues, global temperatures could rise 2.4 degrees Celsius by 2100, far above the Paris Agreement’s goal of a 1.4-degree increase. “Over the past few years, we’ve certainly been trending more towards our ‘discord’ scenario,” Kramarchuk said. “We’re trending toward a longer runway for fossil fuels and less [greenhouse gas (GHG)] emission reductions. This is a case of less GDP growth, less trade and less technology transfer.” Since 1990, world GHG emissions have grown 45%, with mainland China, India and the Middle East representing the biggest increases in emissions, at 304%, 241% and 181%, respectively. Over the last 25 years, the Commonwealth of Independent States and the EU have cut their emissions the most, with decreases of 39% and 31%, respectively. The US has cut emissions 1% since 1990. Of S&P Global Commodity Insights’ three energy and climate scenarios, only one, “green rules,” has global temperatures near the Paris Agreement’s 1.5-degree goa, with an expected increase of 1.7-degrees Celsius by 2100l. The “green rules” scenario, however, assumes more technology transfer, cooperation and policy-driven outcomes than is currently happening. “2030 is not that far away,” Kramarchuk said, “and when you think about what the energy transition will take, solar panels can be constructed fast, but anything beyond that — like an onshore or offshore wind plant or a nuclear unit — we’re getting into lead times of 5, 10, or 20 years.” While the US Inflation Reduction Act has helped speed these transformational energy products along, there are still a lot of slowdowns in permitting, especially in Europe. “We joke that there needs to be a ‘Complexity Reduction Act’ in Europe to move things forward,” Kramarchuk said. Harald Schwager, deputy chairman of Evonik Industries AG’s executive board, added that companies are stuck in a hard place. Evonik has signed power purchase agreements (PPAs) to be powered fully by renewable energy by 2030. “The question will be, will production capacity be hampered by the regulatory process and will we have sufficient infrastructure in place to transport enough renewable power for site demand by then,” Schwager said. Distant peaks Commodity Insights’ energy and climate base case pegs the peak years for coal, oil and gas demand to be 2022, around 2030 and 2040, respectively. “When there is a surprise need for energy,” Kramarchuk said, pointing toward the COVID-19 pandemic and a drought in China, which caused a boost in coal usage, “fossil fuels fill that need.” However, “there’s more investment in renewable capacity than we’re seeing in upstream oil and gas,” Kramarchuk said. Under all scenarios, renewable electricity will be the lion’s share of newly generated energy sourcing. Rebecca Liebert, president and CEO of Lubrizol Corp., said that it is the duty of specialty chemical producers to be agile and proactive in bringing innovative and more sustainable products to market. “Political and technical factors are all things we must account for in our bring-to-market timelines. And we get it right a lot of times, but we get it wrong some of the time. Sometimes you get to market before the market is ready for your product. And I think that’s great, to have a solution on the shelf as the market comes along.” Schwager agreed: “In the specialty chemical industry, we have more good ideas than we have money. And there’s no regret on moves for improved efficiency.” While there has been little movement on target setting and market-based mechanisms for growing renewable energy, COP28’s first global stocktake committee called for “countries to contribute to triple global renewable energy capacity and double global energy efficiency by 2030.” “Even though we are heading for the discord path right now, with all the technology solutions and innovation pushes, we’ll be shooting up ahead towards the ‘green rules’ scenario in the long-term,” Kramarchuk concluded. This article was first published in chemweek.com .

News

Two NGOs appealing against permits Initial plan was to start end of 2023 BASF is facing a delay of the operational start of its newly built precursor cathode active materials (pCAM) plant in Finland due to two non-governmental organizations (NGOs) appealing against already-granted permits, a spokesperson for the German petrochemicals company confirmed to S&P Global Commodity Insights Feb. 27. BASF initially aimed to start commercial production at the Harjavalta plant at the end of last year. “The necessary permit to operate this plant has been granted last year by the relevant authorities,” the spokesperson said. “However, two NGOs have filed an appeal against the already granted permit. Next steps and timing will depend on the furtherance of the judicial process before the Vaasa Administrative Court,” said the spokesperson. The pCAM plant will use renewable energy resources, including hydro, wind and biomass-based power and will be supplied with nickel and cobalt from Nornickel’s adjacent refinery. The plant is part of BASF’s plan to supply the battery industry and subsequently automotive industry with lower carbon emission cathode active material. Platts, part of S&P Global Commodity Insights, assessed cobalt metal in-warehouse Rotterdam at $15/lb on Feb. 26, stable from the previous assessment Feb. 23, while the nickel-cobalt black mass EXW Europe payables was at 54% Feb. 26, also stable.

News

The petrochemical landscape has been transformed in recent years by new technologies and the global energy transition, resulting in numerous production pathways and the development of more sustainable products. S&P Global Commodity Insights has created Chemical Connections , an interactive chart which shows the links between chemicals, from upstream feedstocks to derivative products. The second slide offers a map showing our price assessments and benchmarks for chemicals across the value chain around the world. These prices are used by market participants daily to write contracts, monitor their markets and achieve full transparency around transactions.